Analysis on the design process and reliability of automobile wiring harness发布时间:2021-04-22 10:28:00 浏览次数:2676

Analysis on the design process and reliability of automobile wiring harness

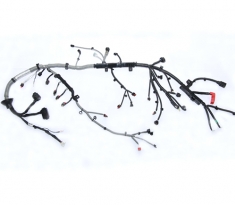

The planning of the car harness is based on the structure layout of the car plastic parts, and then the whole vehicle wiring is carried out. It can be divided into the selection of wires, color, terminals and sheath. Reasonable selection determines the reasonable harness after all

After planning the car harness system, the purpose of saving data, convenient disassembly and maintenance, beautiful layout is realized. The following discusses the planning process and its reliability of the car harness.

Analysis of the planning criterion of the harness of the car

The planning of car harness plays an important role in realizing the function of car and the safety of car driving. Therefore, it is necessary for planners to follow relevant standards in the process of car harness planning. For example, in the process of wire selection, the wires with color matching should be selected, and the wires with color matching can prevent fault identification to a certain extent. The selection of cross-sectional area must be appropriate. It is necessary to select the shortest interval for connection when conducting wire connection, and finally install the wire at both ends of the connector.

Analysis of the planning process of 2 car harness

The whole process of the car harness is: first confirm the electrical functions of the car. After the relevant planners grasp the electrical functions of the car, draw out the electrical schematic diagram, based on which, the first plan of the car harness is carried out in the schematic diagram.

In the process of the planning of the car harness, it is necessary to pay attention to the selection of wires, terminals, connectors, etc. after the planning of the car harness is completed, the vehicle reliability is tested and checked in all directions. If the inspection can reach the relevant specifications, it is necessary to start planning the car harness again and start again if the inspection results fail to meet the relevant specifications

The tests and tests of the reliability.

Analysis of the reliability of harness planning for 3 car

3.1 strictly confirm the length of harness

Car generally confirms the length of each part of the wire harness according to the practical position of the electrical appliance on the body, and all the local places where the harness passes have fixed tie or hole position to fix the harness. So the reliability of the harness is also greatly affected by the size of the branches on the harness assembly. If the harness is too long, it not only wastes space and data, but also causes friction caused by contact with other parts during vehicle driving, which accelerates the abrasion of the harness, thus causing short circuit and other problems; if the harness is too short, it will add the difficulty of distribution, even can not be installed. Sometimes, when the harness is only a little short, the operator thinks that the wire is tightened with force Just go ahead, but this practice left a very big hidden danger to the safety of the harness, which simply caused the single distribution point and terminal looseness, the terminal loose from the sheath, and the connection is not reliable. Therefore, the planning length of the harness must be longer than the practical length

The redundancy is 3-5% in general.

上一页:

Importance of wire selection in automobile wire harness processing

下一页:

Design of power supply for automobile wiring harness